Plastic drip irrigation products are widely used as it saves water and fertilizer by allowing water

to drip slowly to the roots of plants. There are two types water dripper, round

shape water dripper built in dripper system such as size of 2L , 4L , 8L

and 16L per hour for water dripper. This is suitable for lower vegetable

irrigation system. And the other is flat shape water dripper, called on line

dripper system. On line dripper system is suitable for trees irrigation from

2 Meters up to 8 Meters.

|

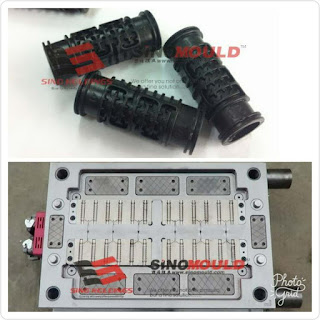

| multi-cavity water dripper molding supplier |

SINO MOULD specialized in offering our

customers with all types of multi-cavity water dripper moulds, such as

24 cavities water dripper mould, 48 cavities water dripper mold, in hot runner

system and cold runner system. We are the most professional water dripper mould

supplier in China with advantage different water dripper design and function,

and advanced mould structure for high speed fast cycle water dripper molding

production. Meanwhile, our European brand high precision CNC equipment are

applied for this pipe drip mold tooling to ensure long time mould life with

high quality.

We provide customers with turnkey solution

for this multi-cavity drip irrigationproducts molding line that comply consistently with quality requirements in

all respects-molds and matching machine, providing training for customers,

technical services for installation &adjustment, which ensure enhanced

customer satisfaction.

If you are interested in starting the water

dripper project, or need order plastic water dripper moulds, please

contact us.

Posted by Ms. Helen

Email: sinoholding@cnmould.com

Whatsapp: 0086 15858625783 (Wechat/ IMO)

Skype: sino.group10