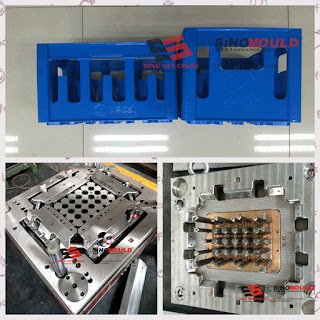

Good quality plastic

crate injection molds is one of our main business areas, together withour perfect molds' design and manufacture, also our sub-company

for design and production customized agriculture crate molding machines

for our customer.

According to our decades experience of turnkey solutions to plastic production line and plant, for one cavity

crate molds, suitable model machines are DKM520SV, DKM650SV and

DKM850SV. Also it depends on vegetable crate dimension and structure, pls

inform us your target crate picture and dimension, our professional team will

help you choose suitable machines .

|

| plastic vegetable crate molding line |

For machine type, we have servo energy saving machines, two plate molding machine and hybrid hi-speed injection machine for one-way thin-wall crate. Compared

with conventional hydraulic machine, our servo energy saving machine can reduce

about 20%-80% energy during injection molding process to save production

cost. Not only save energy, but also realize precise speed and pressure

control. Our middle-large model machine can realize mould opening and ejection

at the same time (parallel action) to increase the production efficiency.

About standard accessories to

machine, we apply famous brand , like KEBA PLC from Austria, oil pump of ECKERLE made in German, photoelectric switch

of OMRON made in Japan… If you plan for plastic vegetable crate production,

pls feel free to contact us.

Posted by Ms. Helen

Whatsapp/ Wechat: 0086 15858625783

Whatsapp/ Wechat: 0086 15858625783

Email: service19@dakumar.com

Skype:sino.group10