How

to start a plastic molding plant? What’s budget at beginning? What’s equipment

you must purchase?What’s factory layout main

point? How to operate these production line with good profits?... There are a

number of issues need to be solved when you’re setting up a plastic milk crate

molding factory. While, you just find Sino Holdings Group in China. Then you

will get customized solution with high speed plastic milk crate lines.

|

| High Performance Plastic Crate Production Supplier |

Why

Sino Holdings Group is China unique professional Turnkey Solution Supplier for

plastic injection molding line?

Compared

with other suppliers of injection molds or molding machines, firstly we already

have more than 10 years experience on providing molding lines of various

projects,

Until

now, we have successfully done over 800 projects in worldwide. Especial for crate

molding lines, our customers are from Spain, Italy, South Africa, Algeria,

Egypt, Turkey, Jordan, Mexico, Brazil, Argentina, Pakistan, Thailand.

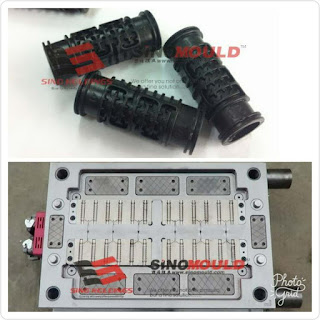

Then,

SINO Holdings Group has two main branches –Sino Mould and Dakumar Machinery,

they are separate management and keen on own line. For belong to one boss, our

cooperation and communication are easy and smooth.

Lastly,

with above advantages, we offer different options.

We

offer a personalized service.

-Purchase

of machinery.

-Advise

on the peripherals appropriate to your needs.

-Robot

programming.

-Start-up

with service adapted to your needs.

-

Transport. Customs. Taxes. it is not sell a machine...

Before

shipment, you will see your milk crate molding line running well at Sino

factory. And we are warmly welcome you come to our company for learning

equipment operation, adjustment, daily maintenance, and loading crate molds and

molds daily operation key points. At same time, our specialized engineering

team could offer whole life service with our local service point at your country.

If you have new project, kindly contact us at present.

Posted

by Ms.Helen

Whatsapp

0086 15858625783 (cell phone / wechat)