With advantages of

famous brand in world molding lines, ten years ago, SINO already extended

business from unique plastic injection molds supplier to comprehensive service

groups. Our vision is to be the world famous supplier for Turnkey injection

molding line with service, technology solution and equipment. Especially for

industry product molding line, find experienced two layers pallet molding line

supplier, double face pallet production line, large pallet molding,SINO Holdings will be your good partner.

|

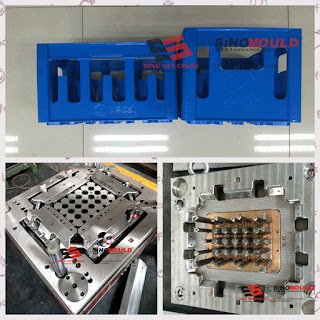

| Double wall pallet molding supplier |

Our

professional team understands well for mold design key points. Such as hot

runner system, in accordance with pallet structure and our experience, we apply

reasonable cavity number with suitable hot runner position to meet your

requirement and save your investment. We have our Anole brand hot runner with

mature technology and prompt service. Also support specified brand as YUDO,

HASCO, DME, Synentiveect. Like for our Korean customer’s two layer pallet, we

applied 17 points sequential valve gate. Equipped with CNC milling center with

milling stroke if 6000*3000*2000mm, SINO has ability to process different sizes

pallet mold at factory.

For

pallet molding machine and auxiliaries, we have different models

machines to meet your demands. Including servo system machines, toggle system

machine, hybrid high speed machine, two-platen hydraulic clamping machine, and

starting testing for full electric machines. We have the huge machines, from

DKM2250-DKM3350T Servo motor for pallet mold testing and mass production. In

2017 year, Chinese largest 4600Ton injection machine will go into service. And

with strong service support, engineering teams support comprehensive service

for setting up new pallet production plant / line with fast and good quality. Including

all equipments installation, adjustment, training and after service. For

turnkey projects, we will show you whole production line running well at our

workshop.

Warmly

welcome your visit and contact for plastic logistical pallet molding service.

Posted by Ms. Helen

Email: service19@sinomould.com

Skype: sino.group10

Cell phone: 0086 15858625783 (Whatsapp /

Wechat/ Line)